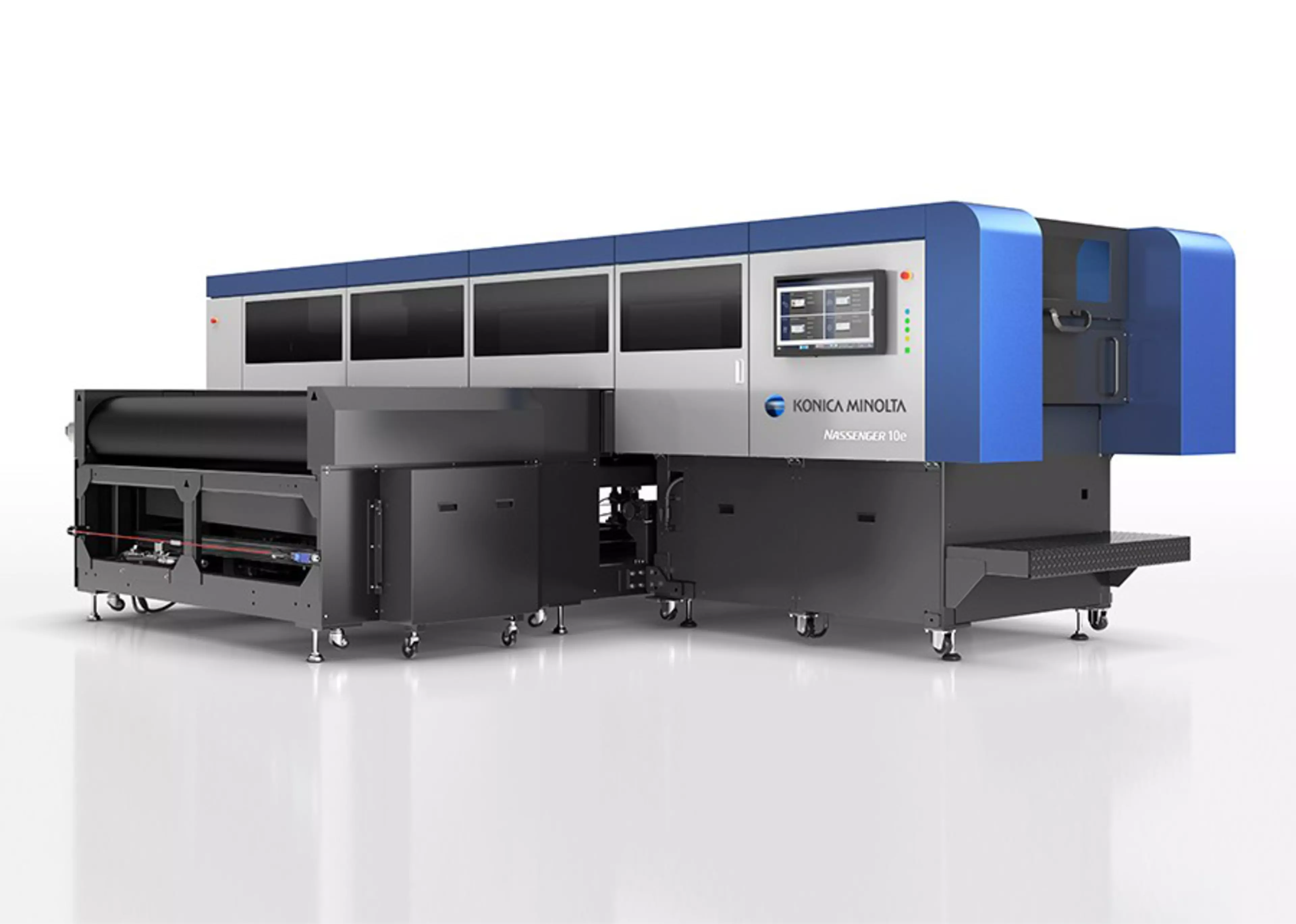

Nassenger 10e

Digital Textile Printing System with High-Speed Scanning. A new way of printing which adapts to the user's needs. Maximum precision, Fast printing time, Simple to use.

- Innovative technology for unprecedented precision

- High speed printing to increase productivity

- Simple to use and maintain

- Maximum reliability

- Improved stability to minimize machine downtime

- High quality ink for faithfully reproduced colors

- Safe and respects the environment